Missouri S&T Satellite Team: Mr & Mrs Satellite

Missouri made. Space grade.

In February 2015, Missouri University of Science and Technology won the Air Force's Nanosat-8 competition, beating MIT, Georgia Tech, and seven other universities. Their winning design: two satellites that would perform proximity operations in space, demonstrating inspection capabilities for non-responsive spacecraft. Nearly a decade later, these satellites are finally ready for launch.

Background

Missouri S&T hired Dr. Hank Pernicka in 2001 to establish their aerospace engineering program. By 2005, the university was competing in national satellite competitions. Dr. Pernicka set clear expectations for his students: "dealing with spacecraft, close to 100% is required for success."

The Missouri S&T Satellite Team (M-SAT) grew from a single course to a 50-person multidisciplinary team by 2015. Their competition history included third place in Nanosat-4 and second place in Nanosat-7, where they notably outperformed MIT.

The Nanosat-8 Competition

The University Nanosat Program, funded by the Air Force Office of Scientific Research, challenges universities to develop flight-ready satellites. Nanosat-8, launched in 2012, focused on proximity operations and space situational awareness – capabilities with direct military applications.

Ten universities competed over two years. The final review occurred January 18-19, 2015, at Kirtland Air Force Base. Winners would receive Air Force launch services for their satellites.

The Mr & Mrs Sat Design

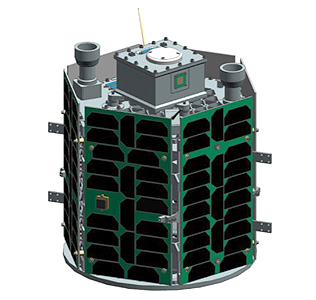

Missouri S&T proposed a two-satellite system:

- MR SAT (Missouri-Rolla Satellite): The inspector satellite

- MRS SAT (Missouri-Rolla Second Satellite): Simulates an uncooperative space object

The mission addresses a practical problem. When satellites malfunction or stop responding, operators need to assess damage without risking astronaut spacewalks or expensive replacement missions. Mr & Mrs Sat demonstrates autonomous inspection at a 10-meter distance.

Key Technical Innovations

Stereoscopic Imaging: Custom dual-camera system creates real-time 3D images, allowing precise position and velocity measurements in space.

R-134a Propulsion: Instead of expensive spacecraft propellants, the team used R-134a refrigerant – the same compound found in automotive air conditioning. The cold gas system, stored in a container roughly the size of a 2-liter bottle, provides six degrees of freedom for formation flying. Cost: about $20 per bottle versus thousands for traditional propellants.

Autonomous Control: The Self-sufficient, Accelerated Spacecraft Integration Flight Control System (SASI FCS) maintains formation without ground intervention, critical for practical operations.

Development Challenges

Dr. Pernicka warned students the project would be "underfunded and due in two years – a ridiculous deadline for normal satellite design." Air Force safety requirements added complexity.

Anna Schroeter, Program Manager, coordinated 9 subsystems and 25+ personnel. Her responsibilities included budget proposals, Air Force coordination, and systems integration across multiple engineering disciplines.

The psychological toll was significant. As Dr. Pernicka noted, "Sometimes they fail spectacularly. It's part of the business." Students invested years in projects that could fail during launch or in orbit.

From Competition to Flight Hardware

Winning in 2015 guaranteed launch services but required transforming academic designs into flight-qualified hardware. This meant:

- Space qualification for every component

- Redundancy for all critical systems

- Testing for launch vibrations, thermal cycling (-100°F to +200°F), and radiation exposure

The process took nearly a decade. By Summer 2024, flight-ready satellites were delivered to the Air Force Research Laboratory. Multiple student generations contributed to the project through graduation cycles and the COVID-19 pandemic.

Mission Profile

The satellites will likely launch on a SpaceX Falcon 9, possibly via the International Space Station. Once deployed, they'll demonstrate:

- Automated proximity operations

- 3D imaging and reconstruction

- Formation flying using low-cost propulsion

Primary mission duration: 4 months

Expected operational life: 2-4 years

Applications include military satellite inspection, commercial satellite diagnostics, and development of future servicing missions.

Educational Impact

The program has produced over 11,000 alumni across 25 years. Many work at NASA, SpaceX, Boeing, and other aerospace companies. Students gain end-to-end spacecraft development experience unavailable in traditional academic programs.

Joseph Nguyen exemplifies the program's reach. A first-generation college student who initially found undergraduate research "a little too challenging," he became Student Director. His scholarship letter stated: "As the first male in my family to attend college, your scholarship will financially assist my family in the expenses of my attendance. I hope to make my community proud and hope to make you proud as a student who dared to change his future."

Technical Significance

The R-134a propulsion system demonstrates how cost constraints drive innovation. If university students can achieve precision formation flying with hardware store refrigerant, the approach could benefit budget-conscious small satellite operators.

The stereoscopic imaging system addresses growing needs for space situational awareness as orbit becomes more congested. Autonomous inspection capabilities have clear national security applications.

Looking Forward

Mr & Mrs Sat awaits launch within 1-2 years. The approaching milestone represents a decade of student effort, technical problem-solving, and persistence through setbacks.

When these satellites finally reach orbit, they'll prove that the greatest space achievements don't always come from billion-dollar budgets or prestigious institutions – sometimes they come from Missouri students with the audacity to make hardware store refrigerant fly. In the cold vacuum above, Mr & Mrs Sat will dance on air conditioning dreams, showing the world that innovation thrives on constraint, that ridiculous deadlines can forge real spacecraft, and that true engineering genius isn't about having the most resources but about having the nerve to reach for the stars with whatever's in your toolbox. They'll orbit as monuments to every student who dared to believe that a hardware store trip could be the first step to space – and that sometimes, the most extraordinary achievements begin with the most ordinary tools.